General Information

Perfec Roll-Up Grates

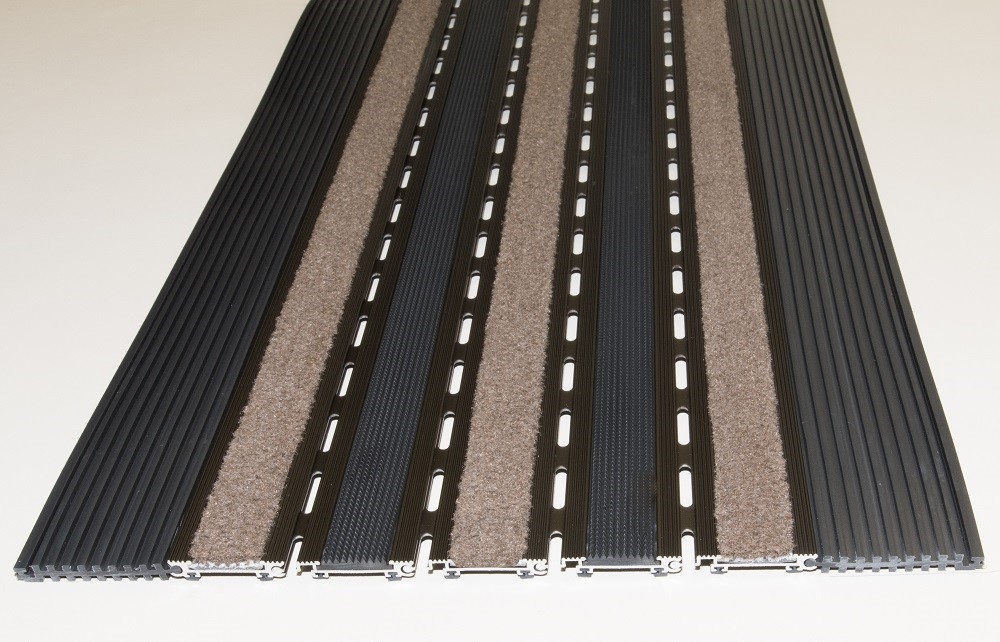

- Recessed Floor Mats – 3/4″ Aluminum Floor Grates are a heavy duty recessed mat that features the rugged benefits of a recessed foot grille combined with the easy maintenance of a roll up aluminum mat.

- 3/4″ Aluminum Floor Grates are CUSTOM Mats, each roll grate is custom made to order.

- The 3/4″ thick Recessed Roll Grate sets into a recess that is deep enough to retain the dirt and liquids that accumulate in high traffic entrances

- Able to withstand rolling loads up to 1,000 lbs per wheel – Making the Roll Grate our heaviest duty aluminum mat.

- Maintenance of the recessed metal floor grate walk off matting is easy – simply roll the mat back to clean – No need to remove the mat from the pit for cleaning.

- Thermoplastic foot pads on the underside of the roll grates prevent “metal to concrete” noise

- Every part of the mat can be replaced or repaired should the mat become damaged.

- Visually, the metal entrance floor grate looks like an aluminum foot grille but features rubber hinges which allow the mat to roll up for cleaning like a 3/8″ thick aluminum roll up mat

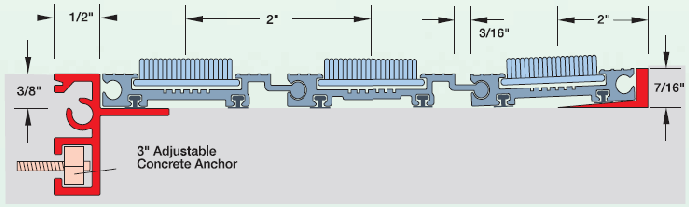

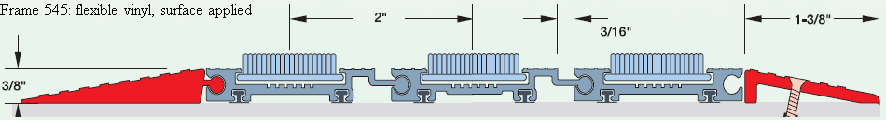

- Available with two different frame options. 448 or 450 See Picture

- **Lead time to fabricate the mats depends on the type of METAL FINISH desired:Standard Mill takes 1-2 weeks, Anodized Finish take 3-4 weeks. **

Frame Options

Frame 450 (Left side of Picture)

Frame 448 (Right Side of Picture)