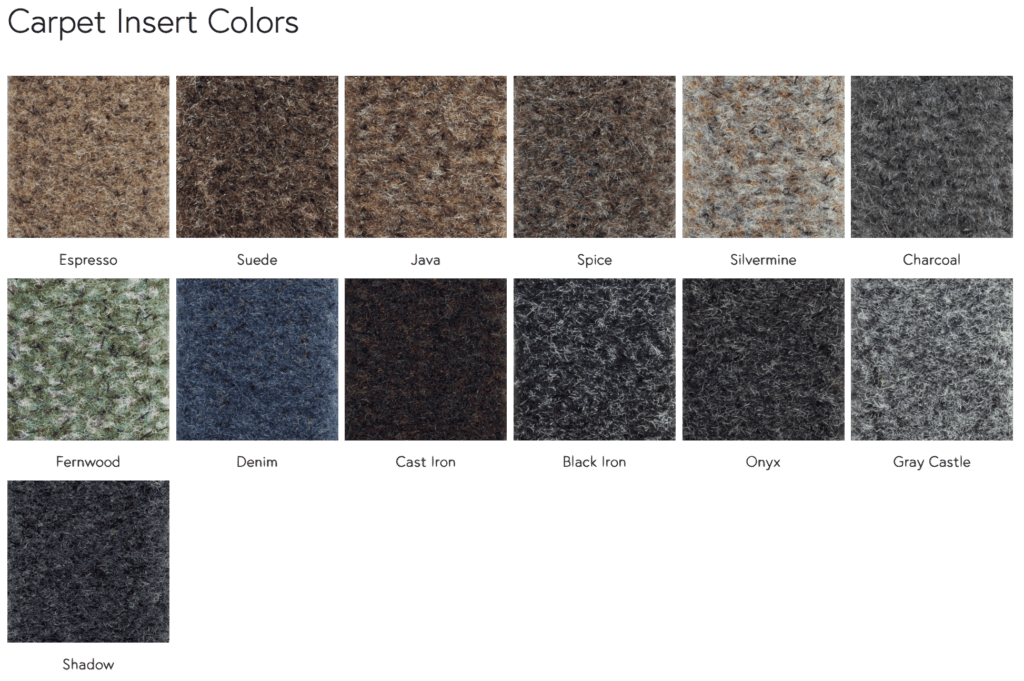

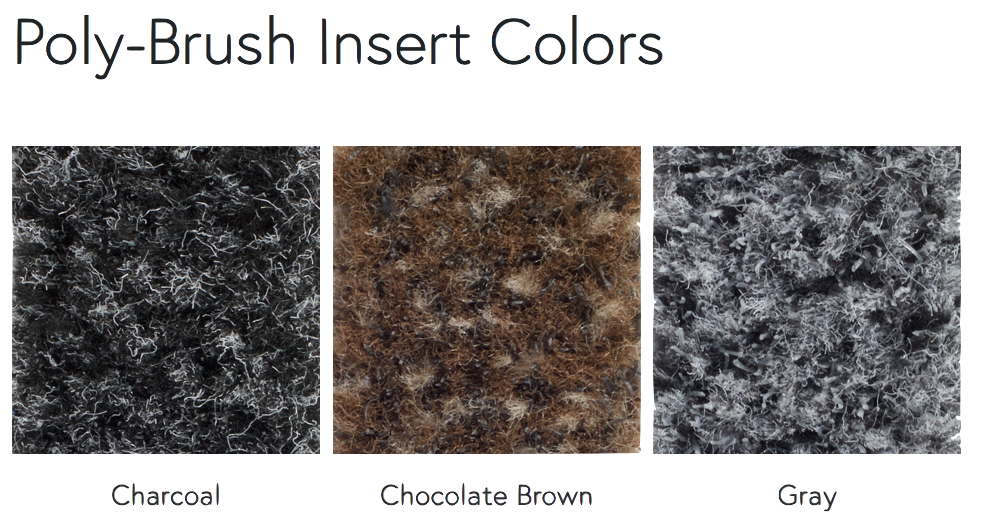

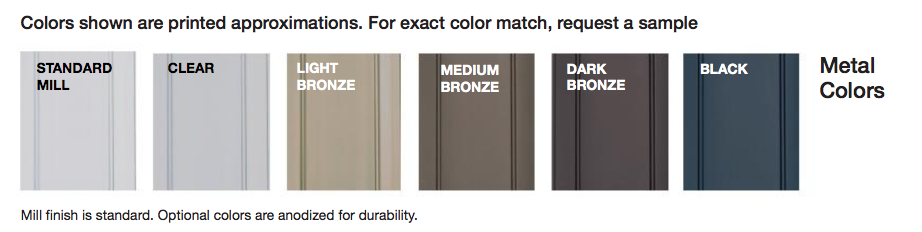

Color Options

PLEASE NOTE: Colors are computer generated and do not accurately match actual insert colors. Please refer to actual color samples.

Cleaning Instructions

Cleaning and Maintenance Instructions Recessed Aluminum Floor Mats

General:

- During the winter season, remove product and clean rails once per week. During other seasons, once per month should be sufficient.

- Debris between the rails should be removed during the cleaning process. Each time the rails are cleaned, make sure there is no debris underneath in the recess; this will prevent product from warping due to an uneven substrate and prevent long-term problems. (Vacuuming is the most effective method for this cleaning.)

- If the units are above a drain, ensure that nothing is blocking the water flow to the drain.

- Never apply wax or other polishing products to the surface of the units; this would create apotential hazard.

Specifics:

- Clean aluminum surfaces with soap and hot water, then allow mat to dry.

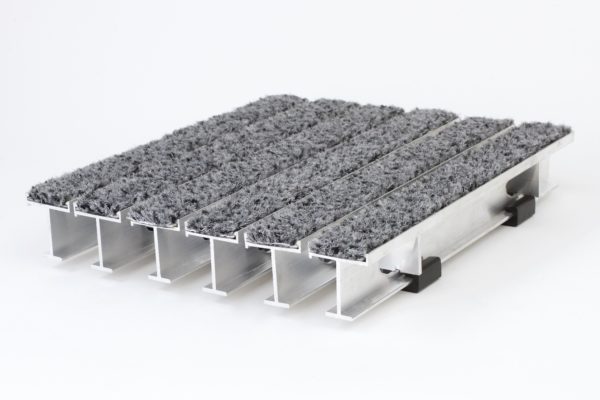

- If applicable, periodically clean carpet and scraping inserts with a hot water extraction machineto remove soil and restore pile.

Exceptions (in addition to above):

- When cleaning products manufactured with rubber hinges (Roll Up Tread 1/2″, Mid-Profile Roll Grate 3/4″ , and Vinyl Hinge Low Profile 3/8″), inspect the hinges and locking mechanism to ensure that all parts are securely attached and are functioning properly. Any parts not functioning properly should be replaced to avoid further problems.

- A stainless-steel cleaner can be utilized, if desired, to maintain surface shine on FootGrille products (stainless steel); Simple Green or Sheila Shine are good options. Just follow the manufacturer’s directions on whatever cleaner is chosen.

Installation Instructions

Guidelines:

Before any installation is started, be sure to verify:

• Model of grid and frame

• Size of grid and frame

• Product color

• There are no visual defects or damage from shipment

Important: No returns will be accepted after the material has been installed.

Failure to follow these installation instructions may void your warranty.

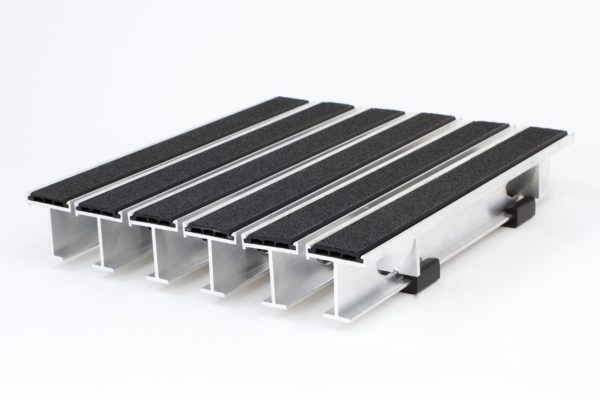

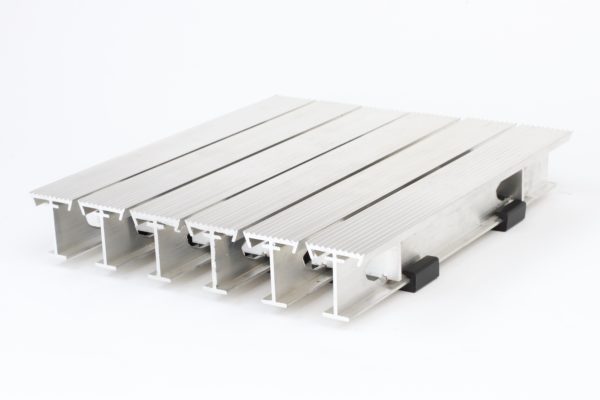

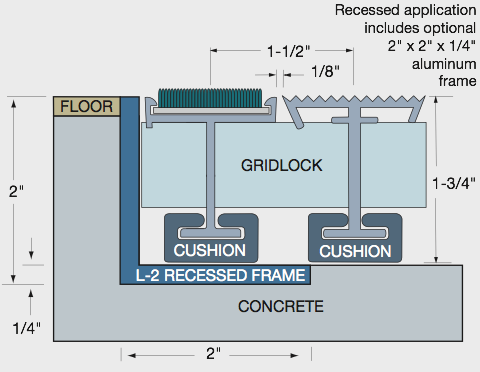

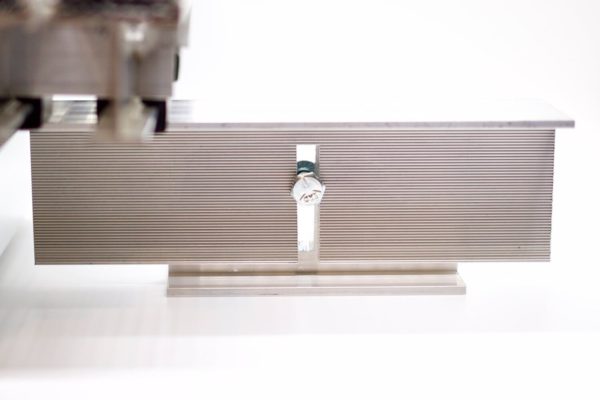

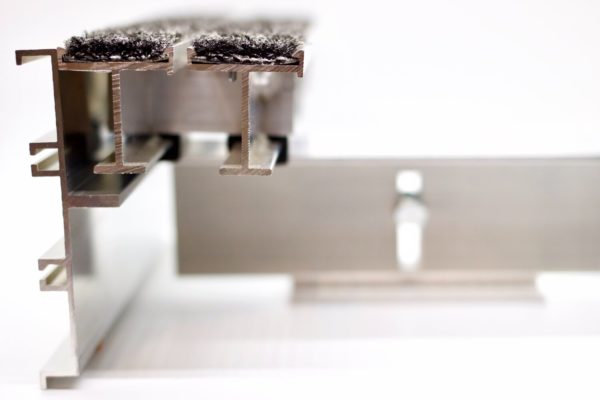

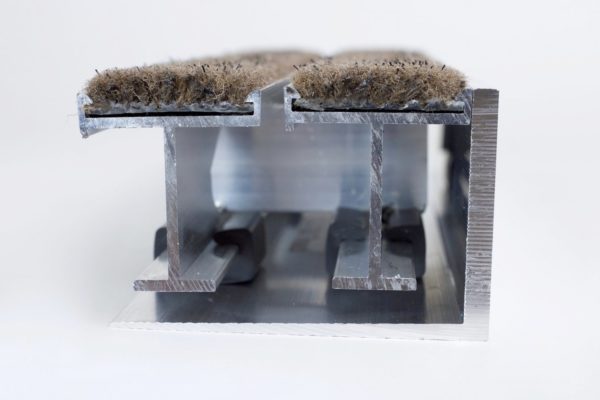

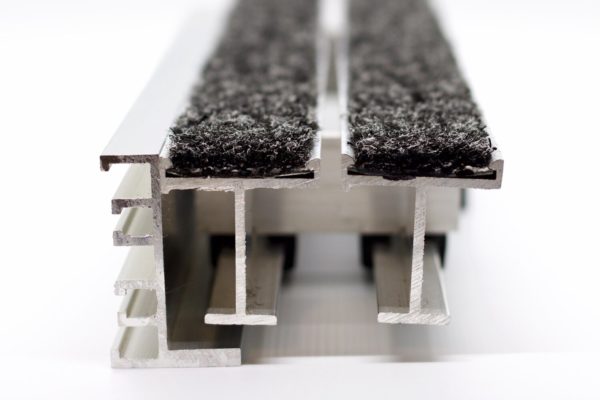

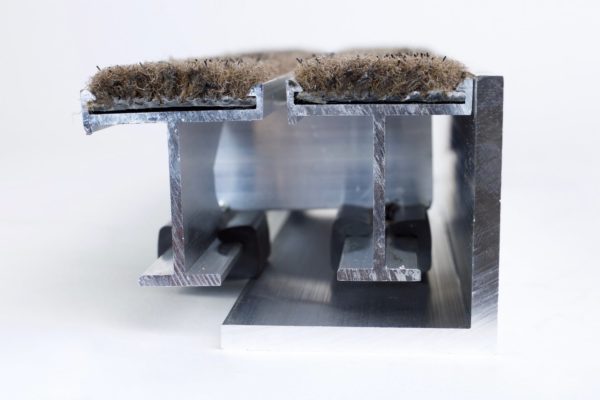

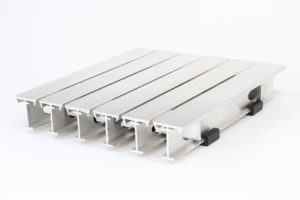

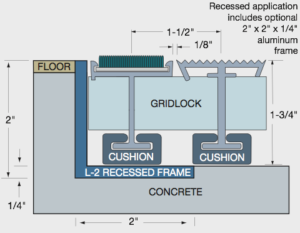

I-Beam Aluminum Foot Grille 1-3/4″ Installations Instructions:

1. Prepare a recess in the concrete flooring (block out) where the grid will be installed. The recess should be at least 1” deeper than the total height of your grid and frame; consult your shop drawing for proper depth. Block out an area 6” wider than the outside dimensions of the frame in both directions. This will allow 3” on all sides to maneuver the frames into place.

2. Place the frame in the recess. Use shims to raise frame to exact height of finished floor and level the frame. All frame corners are mitered.

3. Pour concrete (using non-shrinking grout and coat is not recommended) around perimeter of frame. There must not be any free space between the grid and frame (or the pan if applicable) and the liquid cement.

4. Level the concrete. Frames without pans use a board slightly smaller than the frame opening and level the concrete in each section to be flush with the leg of the frame. It is important the concrete (using non-shrinking grout) is smooth and level with the lip of the frame so the grid lies perfectly flat and will not shift.

5. Ensure there will be no traffic of any kind on the frames during the drying period of the non-shrinking grout.

6. Before the concrete hardens, verify that the dimensions are correct and frame is square and level.

7. After concrete has hardened, install plywood into the recess to fully protect the frame edges until just before the entrance is opened and the grids are installed.

8. Clean the frames and recess before installing grids; debris cannot be tolerated between the frame and grid.

I-Beam FootGrille 1-3/4″ Series Replacement Instructions

1. Remove existing grids from recessed frame.

2. Thoroughly clean ALL debris from the level bed pit of the frame. Use a heavy duty scraper to aggressively scrape accumulated dirt from concrete surface. If pit is not properly cleaned, new grids will rock in place or shift and void warranty.

3. Thoroughly sweep or use a Shop-Vac to clean out loose debris.

4. Once entry pit is fully prepared, remove replacement grids from skid and piece into place.

5. Your new grids will give you quality floor protection if regularly and properly maintained.

I-Beam Foot Grille 1-3/4″ Series Field Fabrication Instructions

1. Place grid to be cut on sturdy tabletop surface. On one end of the table, fasten a straight edge bar or angle piece to serve as a stop edge for one end of the product. Be sure bar is square on the table.

2. Butt one end of the grid tight to bar fastened to table.

3. Measure to your desired length to be cut and mark product with fine tip black marker. Remove black vinyl cushions on bottom of grid if needed for level cutting surface.

4. If trimming only 1⁄4” or so, cut carefully with a portable band saw. Prior to cutting, clamp an additional bar or straight edge to top of product to hold grid steady. If trimming more than 1⁄4” or so, a circular saw with a sturdy carbide-tipped blade will work just as well. Use a straight edge or angle piece for saw to travel against to achieve a nice even cut. Be sure to clamp straight edge to product prior to cut.

5. After cut, clean any smudges or markings with lacquer thinner. If Phillip head screws have been cut off, re-install new screws as needed to secure tread in rails. Brush out ends of tread, then singe with a propane torch (on low setting).

6. Clean up product and return to service.

Warranty

The Mad Matter, Inc warrants to its purchasers, for a period of two years on standard products from the date of shipment, that any entrance floor mat or grid will be free of defects in workmanship and materials. The liability of The Mad Matter, Inc is strictly limited to repair or replacement of the product that, in our opinion, were properly installed and subsequently found defective. The warranty is not applicable if the mats or grids are damaged by overloading or if standard cleaning and maintenance procedures are not respected. No claims for consequential damages of any nature will be allowed. This warranty is in lieu of all other warranties, expressed or implied.

Rolling Load: 400lbs per wheel

Rolling Load: 400lbs per wheel 46% pre-consumer Recycled Content

46% pre-consumer Recycled Content